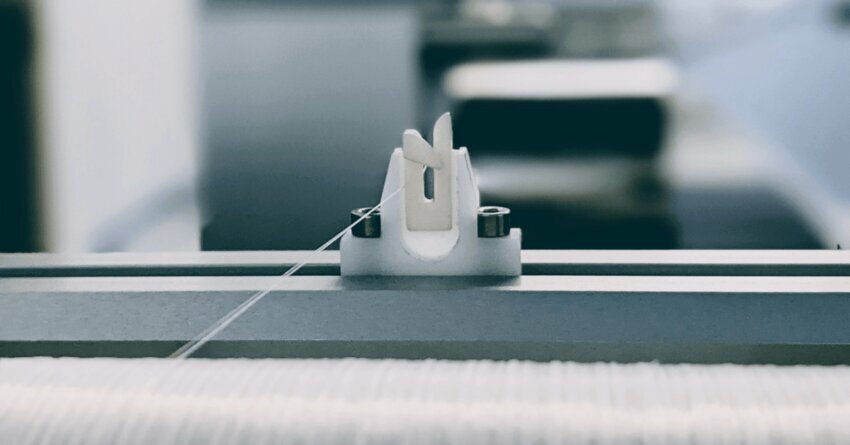

(Credit: Kintra Fibers)

(Credit: Kintra Fibers)In an effort to reduce the environmental impact of the fashion industry, a consortium of industry leaders has partnered with start-up Kintra Fibers. The collaboration aims to explore more sustainable materials and processes, all driven by a shared goal of promoting sustainable fashion.

The start-up successfully raised $8 million in a Series A funding round led by H&M Group.

Additional consortium members include:

The funding will enable Kintra to scale its resin and yarn production capacities to meet the volume demands of its brand partners.

“Kintra's solution aligns with both nature and existing industrial processes, empowering a transformation towards an industry that operates in harmony with the planet. By utilizing bio-based inputs and designing a biodegradable

material from the outset, Kintra addresses the environmental impact caused by traditional polyester at every stage, from production to usage and end-of-life, providing a comprehensive solution for a truly circular fashion industry.” — Alissa Baier-Lentz, COO and Co-Founder of Kintra Fibers

Further, the company's mono-material construction provides all the performance benefits of traditional polyester blended with cotton and spandex, while also making recycling easier.

Kintra Fibers estimates its environmental impact by comparing its raw materials and resin production processes to traditional polyester. Findings indicate its resin production could result in a 95% reduction in GHG emissions, a 30% reduction in water usage, and a 20% reduction in energy consumption.

The team anticipates even greater energy savings when it completes a full life cycle assessment. Given its preliminary analysis did not include yarn spinning, dyeing, or finishing, for which Kintra uses a lower temperature than traditional polyester. Processing the material at lower temperatures could result in the reduction of Scope 3 emissions in the manufacturing supply chain.

Kintra's solution aligns with both nature and existing industrial processes. By utilizing bio-based inputs and designing a biodegradable material from the outset, Kintra addresses the environmental impact caused by traditional polyester at every stage. From production to usage and end-of-life, thus providing a comprehensive solution for a truly circular fashion industry.