Mattel is aiming to cut its normalized carbon emissions by 40 percent by 2015 and 50 percent by 2020, from a 2008 baseline, as part of the company’s first set of measurable sustainability goals.

Mattel is aiming to cut its normalized carbon emissions by 40 percent by 2015 and 50 percent by 2020, from a 2008 baseline, as part of the company’s first set of measurable sustainability goals.

The company also aims to improve packaging material efficiency by five percent by 2015; increase the amount of recycled material and sustainable sourced paper and wood fiber in its packaging to 85 percent, also by 2015; and achieve $25 million in sales of products that use “an environmental enhancement gained through innovation,” with no specified target date. Mattel will define enhancement criteria for packaging and products over the next six months.

The carbon emissions reductions will be calculated from Mattel-owned and operated facilities including manufacturing, distribution and corporate locations of over 20,000 square feet, and will be normalized to sales.

Since 2008, Mattel says it has reduced its absolute and normalized CO2 emissions by 11 percent and 38 percent, respectively. The report doesn’t provide exact figures, but scope 1 emissions fell from about 17,000 metric tons CO2e in 2008 to about 12,000 in 2009, rising to about 15,000 in 2011. Scope 2 emissions were about 200,000 metric tons CO2e in 2008, and since then have fluctuated around the 175,000 mark.

Also since 2008, the company has reduced its absolute energy usage by 3 percent, which it says is a decrease of 33 percent on a normalized basis. Its “resource expeditions” have identified a number of efficiency and renewable energy measures such as using evaporated air cooling systems instead of traditional air conditioners, recycling heat on its molding machines, reusing hydraulic oil, improved maintenance of diesel generators and compressed air systems and transitioning to less carbon-intensive fuels. And as a result of the expeditions, 130-watt high pressure sodium lamps in the Mattel HQ parking structure were upgraded to 64-watt fluorescent lights. The retrofit also equipped each fixture with photoelectric sensors, and reduced energy consumption by 47 percent.

Most of Mattel’s global energy consumption – 82 percent - is associated with its manufacturing operations, followed by corporate offices at 13 percent, and Mattel-operated distribution centers at 5 percent. More than half of its direct energy consumption comes from natural gas.

In 2012, Mattel upgraded its employee shuttle – used to make a 1.5 round trip at its headquarters more than 100 times a day – with a new Ford E450 compressed natural gas shuttle bus. The CNG shuttle now makes more than 95 percent of these trips, and produces almost 30 percent less carbon emissions and 92 percent less hydrocarbon emissions than the older, gasoline-powered fleet.

Since 2008, the company has reduced its absolute and normalized water consumption by 31 percent and 54 percent, respectively. Reductions have been achieved through reuse of cooling water for onsite non-potable purposes, reduced drainage of evaporated coolers, transitioning to less water-intensive manufacturing processes and recycling water in wet tumbling operations. Mattel says it achieved a continued increase in water recycling year-over-year. Again, the company does not provide exact figures, but the report’s charts indicate that Mattel recycled about 18 percent of its water in 2011.

The company has decreased its absolute volatile organic compound (VOC) emissions by nearly 56 percent since 2008, and 70 percent on a normalized basis. Mattel says it accomplished this improvement through the increased use of tampo-style contact printing, more efficient hand spray painting techniques and spray booths, as well as increasing the use of water-based coatings.

Absolute materials use has remained relatively flat over the last four years with a small dip in 2009, primarily related to a slower economy and a decrease in production volumes. In 2011, plastics, resin, packaging and zinc comprised nearly 90 percent of Mattel’s material usage.

Absolute non-hazardous waste generation has increased by 9 percent since 2008, while normalized values have decreased by 30 percent. The decrease in 2009 may be due to lower production volumes, Mattel says.

The company’s cafeterias often serve two to three meals a day, creating a significant disposal burden. Its Monterrey, Mexico plant uses a composting system and since 2010 has diverted more than 15 tons of organic waste a year. The plant also recycles water utilized in the composting process and creates fertilizer to be used on site. Mattel’s headquarters has also implemented a composting program for organic materials and food prep waste generated from its two cafes, and since 2011, has diverted an average of 10 tons of food waste each month from the landfill.

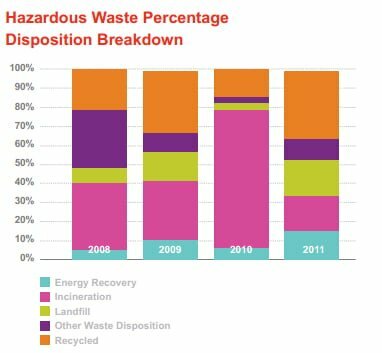

The company's absolute hazardous waste generation has increased by 8 percent since 2008, while normalized values have decreased by 16 percent. Mattel says the increase may be related to the inclusion of facilities whose hazardous waste generation metrics were not included in its previous reporting period of 2004-2008. (For more on hazardous waste, see chart, top.)